Sewage Treatment Excellence

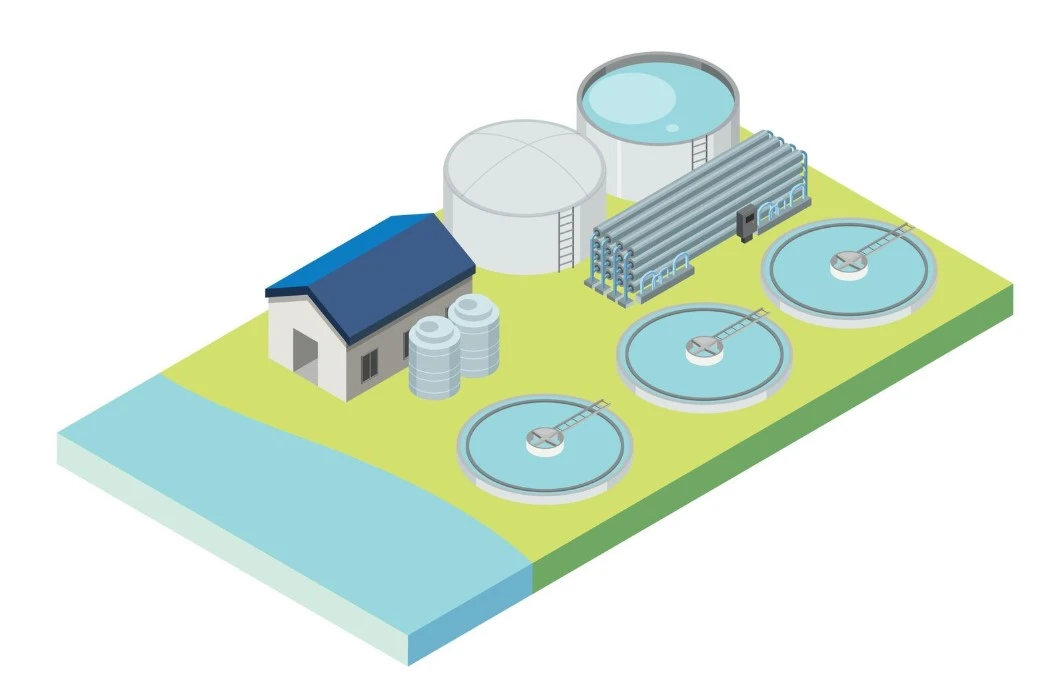

At Acline Group, we turn wastewater into a safe, reusable resource. From community STPs to industrial effluent polishing and residential townships, we design, build, and operate plants that meet strict CPCB norms and future expansion needs.

With decades of multidisciplinary experience, Acline delivers end-to-end STP solutions—concept to commissioning and O&M. Our plants consistently achieve discharge/reuse standards while optimizing footprint, cost, and energy.

Every project begins with a detailed wastewater characterisation, flow studies, and site assessment. We select the right process—MBBR, SBR, MBR, ASP, or hybrid—based on influent quality, space, power, and reuse goals.

Reliability is engineered in. We use corrosion-resistant materials, automated dosing, VFD-based aeration, and robust civil works to ensure stable performance through load variations and monsoons.

Beyond treatment, we focus on safety, odour control, sludge management, and user-friendly operations. Our plants integrate SCADA/IoT for remote monitoring, alarms, and compliance reporting.

Whether its meeting consent to operate, enabling landscape/flush reuse, or achieving ZLD targets, Aclines STPs protect the environment and reduce water stress—for cities, industries, and communities.

Choose Acline Group for proven process design, timely delivery, and long-term O&M support. We do not just treat wastewater—we secure water for tomorrow.

Engineering Clean Water, End-to-End

Aclines STPs are built around a clear process train: screening & grit removal, equalization, biological treatment, clarification/MBR filtration, tertiary polishing, and disinfection for safe discharge or reuse.

We right-size aeration and select diffusers/blowers to cut energy costs. Our PLC/SCADA systems automate cycles (SBR), control DO, and maintain stable MLSS for consistent effluent quality.

Tertiary units—pressure sand filters, activated carbon filters, UF/MBR membranes—deliver low turbidity and pathogen reduction for irrigation, HVAC makeup, and flushing.

Safety first: odour covers, biofilters, non-slip walkways, guardrails, emergency showers, and confined-space protocols align with national and international standards.

Sustainability matters: sludge is thickened/dewatered for composting/co-processing; treated water reduces freshwater intake; solar-ready layouts and energy-efficient equipment lower lifecycle costs.

From brownfield upgrades to greenfield plants, Acline delivers dependable performance—on time, with complete documentation, operator training, and AMCs.

Smart, Compliant & Future-Ready STPs

We align designs with CPCB/SPCB norms, IS codes, and client ESG goals. Our modular civil + mechanical layouts simplify expansion and maintenance without service interruptions.

Each plant includes lab setups, online sensors (pH, DO, ORP, turbidity), and data logs for audits. Remote dashboards enable quick decisions and proactive upkeep.

Where space is tight, we deploy compact MBR or MBBR systems. For fluctuating loads, equalization and automated control stabilize biology and effluent quality.

Community-friendly operation: odour and noise mitigation, neat housekeeping, and clear signage make plants unobtrusive and safe for operators and neighbours.

By prioritizing reuse—gardens, flushing, construction—we help clients cut water bills and strengthen sustainability reporting.

From townships and hospitals to hotels and industrial parks, Aclines STPs keep water cycles circular and compliant.

How We Deliver: From Concept to Long-Term Care

Every Acline STP project begins with a deep dive—comprehensive sampling, treatability studies, and feasibility assessments.

Our proposals clearly outline process design, land footprint, energy needs, and lifecycle costs, ensuring full transparency from day one.

Detailed engineering forms the backbone of our work. From precise P&IDs, GA drawings, and hydraulic profiles to

instrumentation schedules and safety studies (HAZOP/HAZID), we ensure designs that are practical, safe, and future-ready.

Civil structures are built for durability with leak-proofing and robust finishes, while our MEP teams install high-efficiency

blowers, pumps, valves, control panels, and automation systems to global standards.

Commissioning is more than just a handover—we handle biomass seeding, process stabilization, SOP preparation, and operator

training, followed by performance trials to guarantee compliance.

After commissioning, our O&M teams ensure smooth operation with preventive maintenance, calibration, spare management,

sludge handling, and timely regulatory reporting—all backed by SLAs tied to effluent quality and uptime.

For retrofits and upgrades, we integrate energy-efficient aeration, advanced tertiary polishing, or membrane systems

(MBR/UF) to enhance capacity and performance without major civil modifications.

The outcome: safe and compliant discharge, reliable reuse of treated water, reduced operational costs, and peace of mind

for every client we serve.

Process Expertise MBBR, SBR, MBR, ASP, tertiary polishing—selected to match influent quality, space, energy, and reuse goals.

Quality & Compliance Plants built to CPCB/SPCB norms with online monitoring, lab testing, and audit-ready documentation.

On-Time Delivery Clear schedules, prefabricated skids, and synchronized civil-MEP execution ensure timely commissioning.

Safety & Odour Control Enclosures, biofilters, safe access, and SOPs protect operators and communities.

Sustainable Operations Energy-efficient aeration, sludge valorisation, and high-recovery reuse reduce lifecycle costs.

Digital Monitoring SCADA/IoT dashboards, alarms, and data logs for proactive maintenance and assured performance.

Trusted Partner Design-Build-Operate models, AMCs, and retrofit expertise deliver long-term value and uptime.